Farmers have several choices on how to compact their crop (full size modules, smaller modules or round modules). All of them are made so cotton, once picked, can be temporarily stored and transported to the gin.

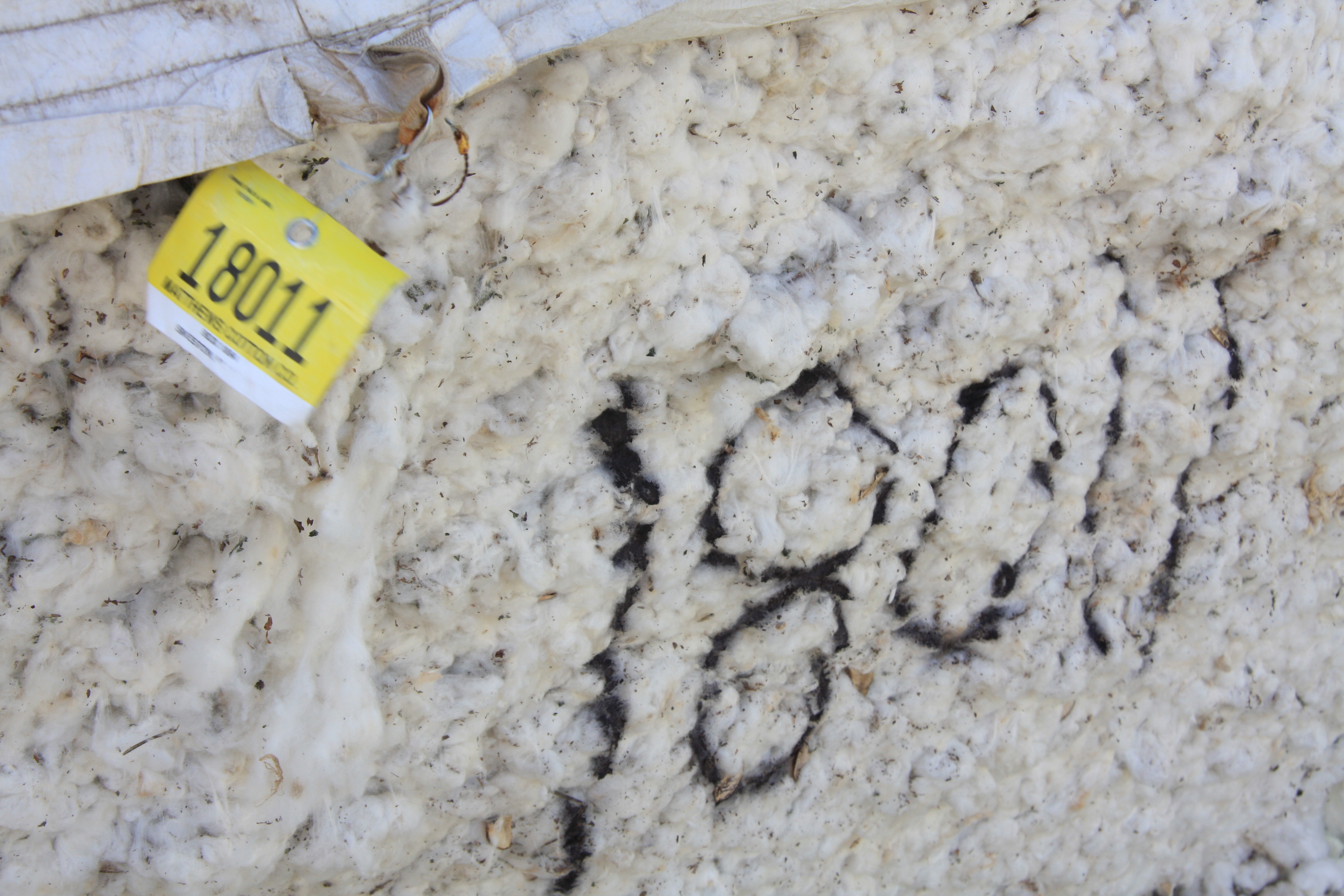

Those modules are tagged in the field to identify what farm & field it came from. You frequently see them tagged with a special kind of spray paint but there are also physical paper tags placed on the module that begin identifying that cotton.

Module weights vary widely based on the equipment producing them.

- The round modules from the on-board baling module picker by John Deere weigh from 4,500 to 5,000 pounds.

- Modules from the on-board moduling picker by CaseIH (small rectangular modules) are 4,000 to 12,000 pounds. (They are 16 foot long.)

- The full size modules are 32 foot long and can be twice as big as the case on-board.

But all modules are transported by the same style truck which looks incredibly light empty as the cargo cover is relatively lightweight as it transports relatively short distances and only needs protect against wind and rain.

There is a creeping floor on the truck and its bed tilts to make loading and unloading easy.

There is a creeping floor on the truck and its bed tilts to make loading and unloading easy.

A cotton gin can process a variety of modules, and you can see various sorts on most. They are typically lined up & organized by the same inventory tagging placed on them in the field. With all the module covers and wrapping to protect them from rain, a gin yard gets to be a really colorful place.

I had someone ask me why gins rush to get the modules in the yard, because they obviously get more in than they can keep up with. Well my thoughts are there are a couple of reasons. First, they need to have enough there to keep the gin running 24/7 for the season. And another is in this part of the world, you never know when the weather will change and make it harder to get in and out of some fields. Next up in the series — ginning!

This is another one of the posts in the cotton 101 series running on the blog. The others include:

This is another one of the posts in the cotton 101 series running on the blog. The others include:

Loved it. Now when I make the drive to Dumas, I’ll know that those things are called modules instead of bales! I’m learning more with each new post!

🙂 I’m looking forward to your cattle series too!

Janice-look forward to seeing you again this year at Dumas and Lorenzo! “Jeana’s Feedbag Catering”