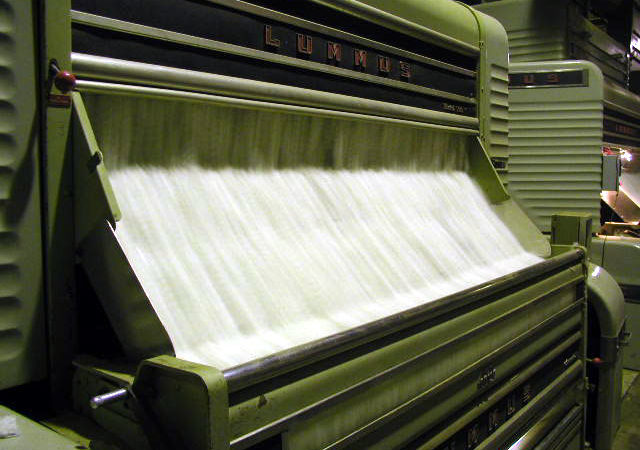

Cotton gins. They haven’t changed the basic function since they were invented but I do know they have changed dramatically in size & speed. At the end of the day, all of them involve separating the seed from the lint. The vast majority of gin use a system of saws pulling lint away from seed and through to a cleaning system. This post includes video & photos.

Cotton 101: Getting Cotton to the Gin

A photo blog of transporting cotton to the gin after harvest. Includes photos of different styles of modules, the ways modules are labeled, and descriptions of the how what and why. The latest part in the Cotton 101 series.

Cotton 101: After Harvest Comes Moduling

An overview of what happens to cotton after its been picked. This is just the field part and includes photos and videos. Includes video of the Case IH on-board module system.

Cotton 101: How Harvest has Changed in a Lifetime

One of the folks I met through the National Agri-Marketing Association, Robert Ratliff, recently help me connect the dots. Robert grew up on a cotton farm and had posted the photo to the left on his Facebook page. The caption on it pointed to a different machine that he used to pick cotton old school. He explained he “remembers ‘Second… Read More

Cotton 101: First Field Basics of the Boll

Video closeup in a field of cotton and some of the bolls off the plant. Talking through the fiber & the plant’s use.

Cotton 101: A Country Girl’s First Farm Visit

My niece’s first visit to a farm at the age of 22. We spent the day in cotton fields watching the farm crew go about their work and even going along for a ride. This is a guest post from her saying what she’s learned.